About us

There is an enormous amount of teamwork involved in guaranteeing consistant quality

For us people really do make the difference, we pay a great deal of attention to the aspect of training because we believe both in our work as well as in that of others. Another crucial aspect is the flexibility of the "Tecnosedia method" allows just-in-time deliveries in order meet the different demands of each one of our clients. Starting from lots of 150 pieces up to those of thousands, we are organized so as to provide the maximum reliability both of the product as well as of the service. We commit ourselves to controlling every phase of the supply chain, trying to carry out as many operations as possible in-house, thus cutting costs and saving time. Currently we are outfitting the upholstery department, with cutting edge CNC machines and with a warehouse that has been built thanks to management systems that are directly linked to customers’ requests. This care that we have striven to have in every aspect produces concrete results, as a matter of fact our chairs have passed the CATAS tests with the standard for the contract even if they are chairs for domestic use. A great teamwork therefore completely concentrated on t he customer’s satisfaction.

Cronistoria

-

1970

Lino Plaino, together with his sons Aldo and Maurizio, founds Tecnosedia.

-

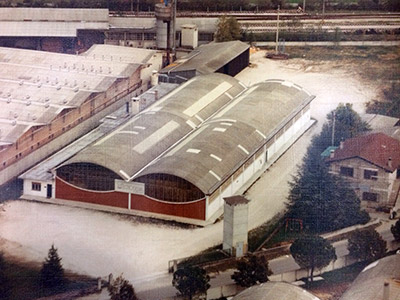

1975

The new headquarters of Tecnosedia, which operates on a 2000 square-meter area.

-

1977

Serenity and conviviality and the milling of unfinished chairs in the background.

-

1996

Tecnosedia’s process of development, which will continue steadily with a constant renewal over the following years, starts with the arrival of the first numerically controlled milling machines.

-

1998

Construction of the first 1,1000 square-meter warehouse. It is equipped with a drive-in racking system.

-

2003

The coating and finish centre is created at the new factory, which uses 2 anthropomorphic robots assisted by conveyor-belts and chains for drying the products.

-

2006

The demands of the marketplace are constantly changing; Tecnosedia has upgraded its solvent plant installations to more eco-friendly ones using an oil finish.

-

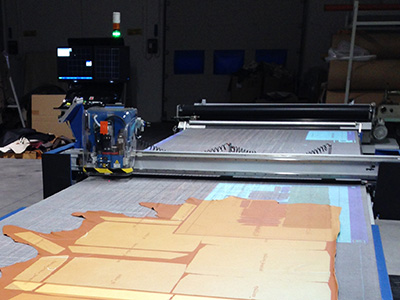

2014

Tecnosedia has further broadened the offering of its production setting up inside its facilities a department that is completely dedicated to upholstery with cutting-edge laser fabric cutting machines.